Innovating for tomorrow

Two technologies, one big impact

We have developed, tested and perfected our innovative technologies in-house.

Our cutting-edge technologies produce sustainable battery materials efficiently, sustainably, and safely.

Two unique technologies, a comprehensive patent portfolio, and a solid intellectual property of our own.

Step 1: Extracting critical minerals

Effective, safe, and sustainable, our extraction solution recovers over 98% of the minerals contained in batteries and creates a black mass ready for hydrometallurgy processing.

Our unique wet shredding technology for recycling lithium-ion batteries was developed in our Centre of Excellence. It generates the most value with minimal environmental impact.

Become our partner

1. The battery casing is removed, and the battery is dismantled into its internal modules.

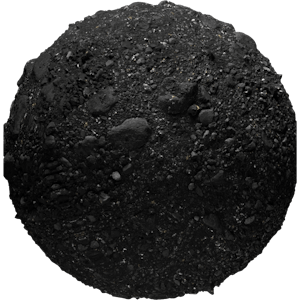

2. The modules are shredded to create a mixture of black mass, plastic flakes and metal pellets.

3. Black mass is filtered from the mix, then pellets and flakes are efficiently separated.

4. The black mass is ready for hydrometallurgy, and the pellets and flakes for recycling.

98

of the black mass is extracted from the batteries.

Concentrated blend of lithium, nickel, cobalt, graphite and manganese

Advantages

A high-performance, safe and unique technology for recycling lithium-ion batteries

Produces a black mass ready for hydrometallurgical processing.

- State of charge – Can handle charged batteries. Eliminates the need to drain batteries, thus avoiding operational slowdowns.

- Type - Simultaneously handles batteries from cars, rechargeable tools, electronics, etc.

- Chemistry - Accepts different battery chemistries in the same batch.

- Shape - Takes complete batteries as well as their components.

- Reduces the risk of thermal runaway and chemical reactions.

- Prevents maximum airborne particles.

Adaptable to changes in battery chemistry and technology.

Once the batteries are on the conveyor, no manual operation is needed for the rest of the process.

Our technology in action

Our proven technology is demonstrated daily at our commercial extraction plant, Lithion Saint-Bruno.

Step 2: Producing high-purity materials

We have reinvented hydrometallurgy and created our patented technology to produce strategic battery-grade materials. We make recycling lithium-ion batteries safer and more sustainable.

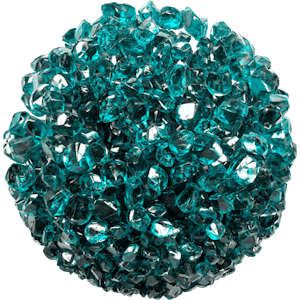

The black mass resulting from our extraction process is put through our hydrometallurgy process to produce lithium carbonate, nickel sulphate and cobalt sulphate of comparable purity to that of metals extracted from the ground subjected to the same processes. Our team is ready to work with future partners and adapt these salt forms to their requirements.

Our cutting-edge hydrometallurgy technology, created by our specialists at our Centre of Excellence, sustainably produces high-purity strategic materials, making us very proud.

Become our partner

1. Black mass is dissolved in a liquid, and graphite is separated from the mix to isolate strategic materials.

2. The mix of strategic materials is purified.

3. The purified solution is subjected to various extraction processes to generate three battery-grade strategic materials: lithium carbonate, and nickel and cobalt sulphates. Industrial-grade manganese and sodium are also produced.

4. Finished products are packaged and shipped to users in the battery production chain. Lithion closes the loop of battery materials.

99

Purity greater than

Over 98% recovery of all valuable materials

- Battery-grade lithium carbonate

99

Purity greater than

Over 98% recovery of all valuable materials

Battery-grade cobalt sulphate

99

Purity greater than

Over 98% recovery of all valuable materials

Battery-grade nickel sulphate

Lithion Centre of Excellence

Lithion’s technologies were fully elaborated, tested and perfected in our industrial-scale Centre of Excellence.

From the beginning, having our state-of-the-art research team and facility was a matter of course to keep control of our technologies, have the flexibility to adapt them to technological evolution, and confidently guarantee our results.

Our Centre of Excellence is the source of our success.

Smaller environmental impact

Our commitment is profound and sincere. We develop and deploy our technologies with environmental protection in mind.

We want to do what's right, the right way.